Margarine production line modernization is essential in 2025 as the global margarine industry faces rapid changes driven by shifting consumer preferences, rising demand for healthier options, and stricter food safety regulations. Today, modernization is not a luxury but a necessity for staying competitive, enhancing operational efficiency, and complying with evolving standards. By embracing margarine production line modernization, manufacturers can ensure their facilities remain profitable, adaptable, and ready for the future.

In addition to these trends, there’s a growing emphasis on traceability, sustainability, and digital integration. Customers, retailers, and regulators alike are demanding more transparency and accountability in food production. Upgrading to a modern margarine production line ensures that companies can collect and report data on every stage of manufacturing, from raw material sourcing to final packaging.

Key Drivers Behind Margarine Production Line Modernization

Modernizing your production line offers multiple advantages. Firstly, automation and digital control systems can significantly reduce human error, enhance consistency, and optimize resource use. Secondly, energy-efficient machinery lowers operating costs and reduces your environmental footprint. Finally, updated equipment allows you to expand your product range by supporting new formulations and packaging technologies.

Another key driver is the need for flexibility. Today’s consumers expect variety—from plant-based spreads to organic margarine with low-fat content. Legacy equipment is often too rigid to accommodate rapid changeovers or small batch production. Modern lines are designed to switch between recipes and packaging formats with minimal downtime.

Evaluating Your Current Production Setup

Before investing in modernization, conduct a comprehensive audit of your existing infrastructure. This includes evaluating equipment performance, downtime rates, maintenance costs, and compliance with food safety standards. Identify bottlenecks, inefficiencies, and outdated machinery that hinders productivity. Such an assessment will inform the scope and scale of your modernization project.

A full evaluation should also cover logistics, such as how raw materials are received and stored, how finished products are packaged and shipped, and how data is tracked across departments. A digital maturity assessment can be particularly helpful in determining which areas of your production line are already Industry 4.0-ready—and which need attention.

Step-by-Step Guide to Margarine Production Line Modernization

1. Define Your Modernization Goals

Do you aim to increase output, reduce waste, or improve product quality? Setting clear goals will guide equipment selection and process design. Some companies may prioritize sustainability and energy efficiency, while others may focus on reducing labor costs or expanding product lines.

2. Choose the Right Technology Partners

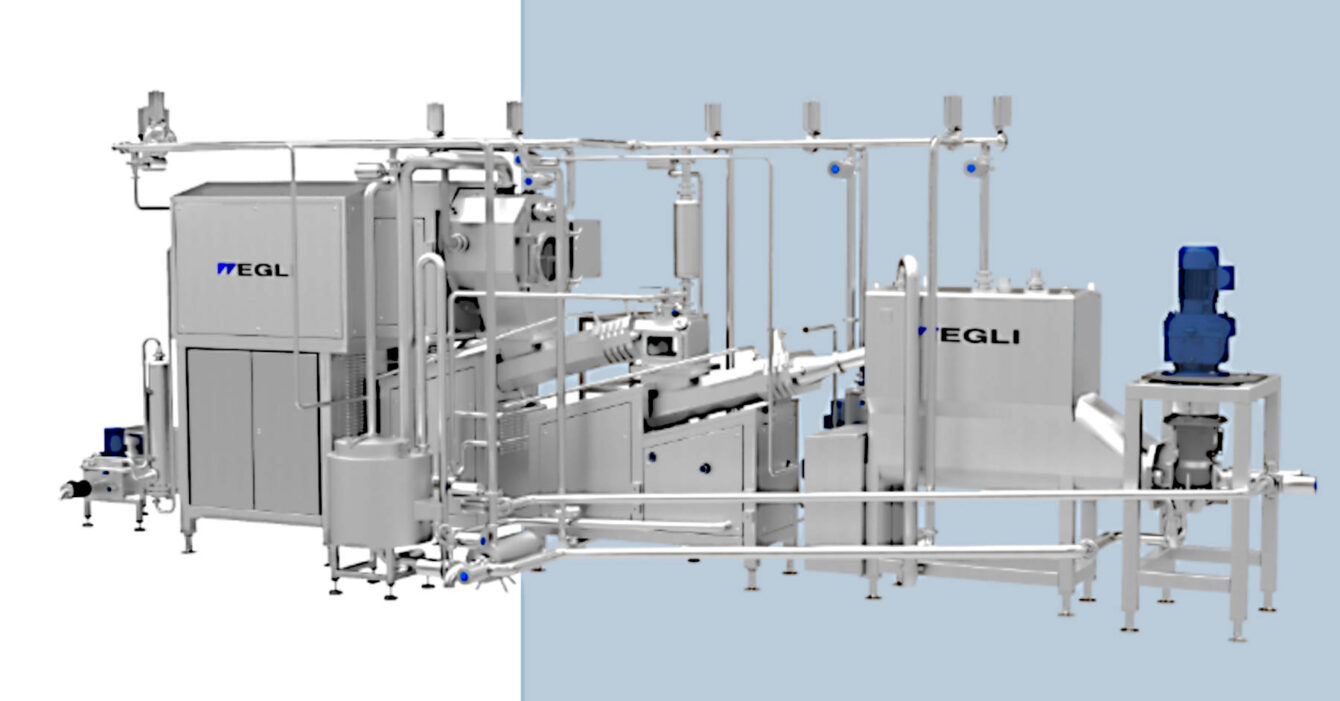

Collaborate with reputable equipment manufacturers who specialize in margarine production line modernization. Swiss engineering firms, such as Egli AG, offer tailored solutions backed by decades of expertise. These companies can also assist with feasibility studies, ROI projections, and regulatory compliance.

3. Invest in Automation and Smart Systems of Margarine Production Line Modernization

Integrating PLCs (Programmable Logic Controllers), SCADA systems, and IoT sensors enhances process monitoring, real-time data analysis, and predictive maintenance. These systems help identify equipment wear before failures occur, reducing unplanned downtime and increasing operational reliability.

4. Prioritize Hygiene and Food Safety

Modern lines should comply with HACCP and EHEDG standards. Hygienic design not only ensures product safety but also simplifies cleaning and reduces downtime. Seamless welding, sloped surfaces, and easy disassembly are key features to look for.

5. Train Your Staff after Margarine Production Line Modernization

Upgrading technology is only effective when your team is equipped to operate and maintain the new systems. Ongoing training programs are vital. This includes both technical training on new machinery and cross-functional training to improve team collaboration across production, quality control, and maintenance.

Cost-Benefit Analysis: Is It Worth the Investment in Margarine Production Line Modernization?

While the upfront cost of margarine production line modernization can be substantial, the long-term ROI justifies the expense. Companies that modernize benefit from reduced operating costs, improved product consistency, and increased production capacity. Moreover, modern equipment often comes with remote support and diagnostics, further minimizing unplanned downtime.

In addition, energy savings can be significant over the lifespan of new machinery. Variable speed drives, heat recovery systems, and low-energy motors reduce consumption. Savings in packaging materials, improved yield rates, and fewer product recalls also contribute to a compelling business case.

Case Study: Success Through Modernization

A mid-sized margarine manufacturer in Eastern Europe recently partnered with Egli AG to modernize their production line. The project included installing a new emulsification system, integrating automated filling machines, and upgrading their CIP (Cleaning-in-Place) units. Within six months, the company reported a 25% increase in output and a 30% reduction in waste, demonstrating the tangible benefits of margarine production line modernization.

Additionally, the company was able to introduce two new product lines and reduce their carbon footprint by switching to a more energy-efficient cooling process. The ability to meet new EU labeling and traceability standards also opened doors to export markets previously out of reach.

Avoiding Common Pitfalls of Margarine Production Line Modernization

Modernization can be complex, and poor planning may lead to production disruptions. Avoid these common mistakes:

- Underestimating downtime during installation

- Choosing incompatible components

- Neglecting staff training

- Ignoring long-term scalability

Careful project management and phased implementation can help mitigate these risks. Pilot testing, digital twins, and simulation modeling are increasingly used to plan upgrades with minimal disruption.

Another common error is underestimating the cultural shift required for digital transformation. Involving frontline operators and maintenance staff in the design process helps build ownership and reduces resistance to change.

Future-Proofing Your Production Facility

The pace of innovation in food processing technology is accelerating. To remain competitive, businesses must embrace continuous improvement. Margarine production line modernization is not a one-time event but an ongoing process. Consider modular systems that can be upgraded easily as new technologies emerge.

Future-proofing also means investing in systems that support traceability, digital integration, and cloud-based analytics. These tools enable remote diagnostics, better forecasting, and stronger quality assurance. Cybersecurity is another emerging consideration for connected factories, requiring robust firewalls and data protection policies.

Sustainability as a Key Driver of Modernization

In 2025, sustainability is no longer a trend—it’s a business imperative. Consumers want to know the environmental impact of the products they purchase. A modern margarine production line can significantly reduce energy use, water consumption, and waste.

Using lifecycle analysis and carbon footprint assessments, companies can quantify the sustainability benefits of modernization. Recyclable or biodegradable packaging, optimized use of ingredients, and more efficient heating and cooling systems all play a role.

Conclusion: Invest Today for Tomorrow’s Success

In 2025, staying ahead in the margarine industry means investing in efficient, flexible, and compliant production systems. Margarine production line modernization empowers manufacturers to meet evolving market demands while improving profitability and sustainability. The time to act is now—modernize your margarine production line and secure your competitive edge for years to come.

Whether your goals are innovation, compliance, cost reduction, or market expansion, the journey to modernization begins with a single step: committing to a smarter, more sustainable way of producing margarine.